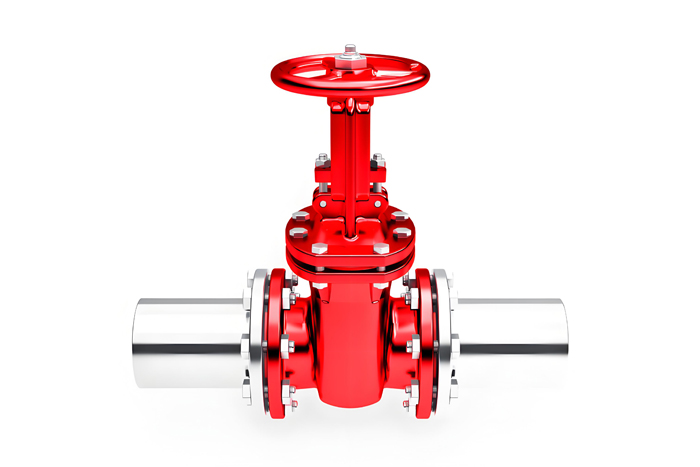

Gate Valves: Essential Shut-Off Solutions for Industrial Systems

Gate Valves are critical shut-off devices in fluid control systems. By raising or lowering a gate plate, they enable precise flow regulation with minimal resistance. Known for their robust sealing, simple design, and low fluid friction, these valves are indispensable in oil/gas, power generation, chemical processing, and water management pipelines.

Understanding Gate Valve Types: A Comprehensive Classification Guide

Gate valves are essential components in fluid control systems, categorized primarily by their structural design, sealing method, actuation type, connection style, and construction materials. This guide explores the key classifications to help you select the optimal valve for your application.

I. Classification by Structural Design

- Wedge Gate Valves:

- Solid Wedge: Features a simple, one-piece design. Offers reliability but requires precise sealing surface angles. Temperature fluctuations can sometimes cause binding (wedging).

- Flexible Wedge: Incorporates a cut around the perimeter (annular groove), providing enhanced elasticity. This design compensates for thermal expansion/contraction, improving performance across varying temperatures and pressures.

- Split Wedge (Double Disc): Uses two independently seated discs. This allows automatic compensation for minor sealing surface wear, extending service life. Best suited for lower viscosity fluids and steam service; the mechanism is more complex than solid wedges.

- Parallel Slide Gate Valves:

- Automatic Sealing Type: Relies solely on line pressure to force the parallel discs against the seats for sealing. Simple and robust construction.

- Mechanical Sealing (Expanding Gate) Type: Utilizes a spreading mechanism (often a wedge between the discs) that forces the discs outward against the seats as the valve opens, creating positive sealing independent of line pressure.

- Rising Stem vs. Non-Rising Stem:

- Rising Stem Gate Valves (OS&Y): The stem threads externally, causing the stem to rise visibly out of the valve body when opened. Provides clear visual position indication and simplifies lubrication/maintenance.

- Non-Rising Stem Gate Valves (NRS): The stem threads internally into the gate. The stem only rotates during operation, with no upward movement. Ideal for installations with limited vertical space (underground, compact systems).

II. Classification by Sealing Method

- Soft-Seated Gate Valves: Utilize resilient sealing materials like EPDM, NBR rubber, or PTFE (Teflon) for the seat/gate interface. Deliver exceptional bubble-tight shutoff, even at lower pressures. Highly resistant to corrosion and ideal for water, chemicals, and gases where zero leakage is critical. Generally not suitable for very high temperatures.

- Metal-Seated Gate Valves (Hard-Sealed): Feature metal-to-metal contact between the gate and seat (e.g., stainless steel on stainless steel, stellite overlays). Engineered to withstand extreme temperatures, high pressures, and abrasive media. While offering excellent durability, absolute zero leakage can be harder to achieve consistently compared to soft-seated designs. Common in steam, oil & gas, and high-temperature applications.

III. Classification by Actuation Method

- Manual Gate Valves: Operated by a handwheel or lever. The simplest and most cost-effective solution for readily accessible valves requiring infrequent operation.

- Electric Gate Valves: Powered by an electric motor actuator. Enable remote operation, automation integration, and precise control. Essential for large valves, hazardous locations, or automated processes.

- Pneumatic/Hydraulic Gate Valves: Utilize compressed air (pneumatic) or pressurized fluid (hydraulic) for actuation. Offer rapid open/close cycles and generate very high torque, making them suitable for demanding applications requiring fast response or handling high differential pressures.

Core Applications

Gate valves excel in:

1. Flow Isolation: Fully open/close positions for on/off control.

2. High-Pressure/Corrosive Environments: Withstand extreme temperatures and aggressive media.

3. Adjustment Scenarios: Limited flow modulation (though throttling is not their primary function).

Selecting a Quality Manufacturer

Partner with certified manufacturers for longevity and performance. Key considerations:

1. Material Quality: Cast iron, carbon steel, or stainless steel for corrosion resistance.

2. Technical Expertise: ISO/API-compliant production processes.

3. Customer Feedback: Proven reliability in high-stress applications.

Price Factors

Gate valve costs vary based on:

1. Materials (e.g., carbon steel, stainless steel vs. cast iron)

2. Size/Pressure Ratings (DN50 to DN1200; 150 PSI to 2500 PSI)

3. Special Features: Fire-safe design, cryogenic compatibility.

Tip: High-performance valves offer long-term savings via reduced maintenance.

Leading Chinese Manufacturers

1. Newsway (NSW) Valve Co., Ltd.

Founded in 2003; exports globally. Specialties: Nuclear-grade valves, gate valves for oil/gas/chemical industries.

2. Suzhou Neway Valve Co., Ltd.

Focus: Nuclear power valves, petrochemical solutions.

3. Shanghai Qizhong Valve

Expertise: High-temperature/pressure gate valves for power/water sectors.

4. Jiangsu Shentong Valve

Innovations: Nuclear-grade butterfly/ball valves, metallurgical valves.

Factory Insights

Visiting a gate valve factory reveals:

1. Quality Control: Raw material checks to final packaging.

2. Automation: CNC machining and AI-driven assembly lines.

3. Certifications: API 600, ASME B16.34, ISO 10434 compliance.

China’s Market Advantage

1. Global Supply: 40%+ of industrial valves exported worldwide.

2. Innovation: ”Made in China 2025″ drives smart, eco-friendly designs.

3. Cost Efficiency: Competitive pricing without compromising durability.

Purchase Checklist

1. Usage Needs: Match materials/pressure ratings to media (water, steam, chemicals).

2. Connection Type: Flanged, threaded, or welded ends.

3. Certifications: API, ISO, or industry-specific standards.

4. After-Sales Support: Warranty, technical assistance, spare parts.

Maintenance Best Practices

1. Routine Checks: Inspect for body corrosion, gate wear, and seal integrity.

2. Prevent Sticking: Exercise valves quarterly if inactive.

3. Lubrication: Apply valve-compatible grease to stems/seats.

4. Critical Fixes: Replace worn gates/seats to prevent leaks.

Conclusion

Gate valves remain vital for safe, efficient fluid control across industries. By prioritizing certified manufacturers (like NSW or Suzhou Neway), understanding price drivers, and implementing proactive maintenance, operators ensure system reliability. China’s valve industry—backed by innovation and stringent standards—delivers cost-effective solutions for global infrastructure.

Explore top gate valve suppliers today to optimize your fluid systems!

Post time: Feb-17-2025